Please read all the information......it will save you alot of money and heartache.

Pros and cons

From Dave Derer...

My favorite re-power is the ninja 650. I was going to go all electric, but so danged expensive.

So my next plan is to re-power with a Suzuki 650 and use an electric hub motor for reverse. I can build that economically.

Electric

New technology is helping with the hub motors. They were too small, but they are increasing. You could also use an electric motor with belt or chain running rear wheel.

Florida states that conversions need to be 96 volt minimum. Batteries....the Tesla packs can't be rearranged, but leaf and prius cells can. You would have to study how much a hub motor can actually carry weight wise.

If using goldwing wheel, I would build frame to fit modules. Teslas could fit. But I like the Prius because I can repair individual cells.

In 2020, it appears Prius is a bit more affordable. You will need BMS..... Battery management system.

There is a whole learning curve there! Orion will pop up on YouTube videos.

They are big $$$. I have been looking at eBay 18650 bms pcb board balance. You will see a number like 13s 24s 28s that stand for cells.

I am buying the 28s for my Prius pack that I use on my Ampicar EV. So I can balance and charge outside of car.

Don't forget you will need charger too. Also a converter from I.e. 96 v to 12volt. 12volts is needed for bms and lights.

I like EV West for information.

If your Pulse has a Yamaha 400cc engine, the following engine replacements may work with little modifications.

Honda 650 automatic .... great engine with no shifting, but if you need to change the belt, you have to remove engine.

Honda 1100......Good proven powerplant. Many Pulses are powered with this engine from the factory.

Honda 1200.....Good proven powerplant. Several Pulses are powered with this engine from the factory.

from Scott Enerson…......if you decide to re-power your Pulse with a Honda 1200cc, look for a 1986 or 1987. Both the 1984 and the 1985s had carburetor problems. I would use only the top of the line Aspencade which has a 7 digit odometer. So you can tell how many miles are really on the bike. I found one with 30,000 miles in 2022 for $800, and perfect running carbs. Facebook Market Place is just full of bikes. Anything newer will not have a steel, two sided swingarm to mount your reverser on to.

Honda 1500......Frame and body work needed with this engine.

BMW ...... not sure what modifications needed

Kawasaki......not sure what modifications needed.

VW................some owners have converted their Pulses to a trike using the VW engine and rearend.

The Scranton built Litestars were powered with a 450cc Hondamatic

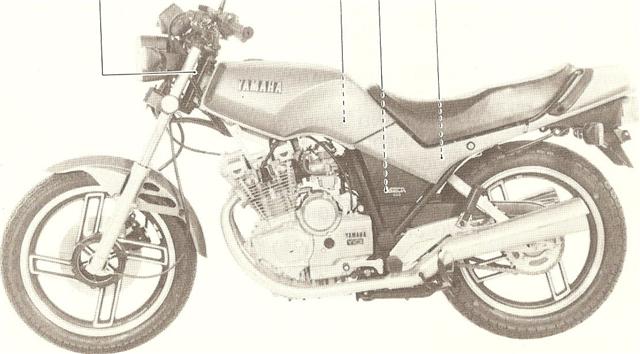

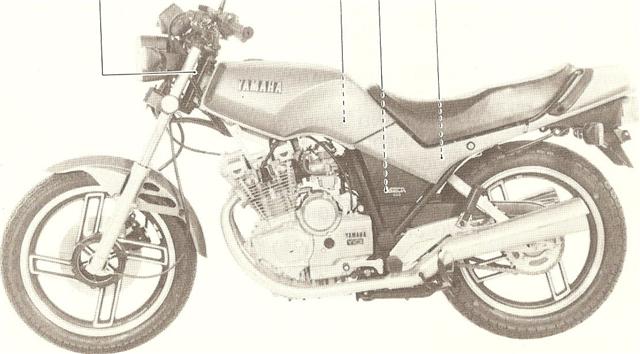

All Owosso built Litestars and Pulse vehicles #22 thru #260 were originally supplied with the Yamaha 400cc air cooled engine. At the start of production in early 1985, OMCC had to buy the complete motorcycle, so they chose the new 1982-83 old-stock Yamaha 400cc bikes. Yamaha would not sell just the engines.....unless you wanted to buy several thousand.

So they used as much of the bike as they could, turn signals and gauges, etc. The Yamaha 400 motors had vastly different HP ratings from 1985-1986. The 1985 model started using an XS400 motor that made 35 HP, then the XS400R (aka Seca) made 45 HP.

The easiest way to tell the engine model is the XS model has vertical cylinders and the R model has 10 degree inclined cylinders (with dual overhead cam and counterbalanced).

This turned out be a poor choice because it is air-cooled and with the enclosed rear end of the Pulse, this engine will overheat in warmer temperatures.

But several owners with the Yamaha 400cc engine have found various ways to help cool their engines with fans, better grades of oil and more vents.

Most factory built Pulses from #261 to the end of production had Honda water-cooled engines such as the 500cc, 1100cc or the 1200cc. This is a much better engine choice, but it will also overheat in slow parades when the temperature is in the 90's.

Today, many Pulse owners are re-powering their cars with the Honda 1100cc or 1200cc with a couple fans pointed toward the engine to eliminate overheating.

Some owners are also considering the 1500cc Honda engine which has the reverse gear already included.

Others have had success with Kawasaki 750cc or the hot Honda V65. Below are a few of the stories from owners regarding RE-POWERING of the PULSE.

These tips are from an authorized Honda Dealer and Pulse Club Member......Pete Hatfield of Muscatine, Iowa

The stators on the 1200 (1984-1987) Gold Wing engine are far more prone to failure than the alternators on the 1100 engine. If you are getting a new engine, you would be better off, in my opinion as a Honda Dealer, to go with the 1100. The stator replacement is an expensive, engine out job on a two wheeled Gold Wing. It is a downright nightmare in a pulse.

In 2009, I will become the first Pulse owner to do an 1800 Gold Wing engine convert. 118 horsepower, fuel injection with built-in electric reverse.

How I Cooled the Yamaha 400 Engine....by Don Sucha

Pulse #171 is owned by Don Conley of Amarillo, Texas and installed a 1997 Honda ST1100 in 2005..............

I talked with Dave Baur a couple of years ago and also Don Muddiman about using a Honda ST1100. Its now in and I gave up about 1 1/2 inches in the back seat, and the rear wheel at the rear most fiberglass shell. We installed it to remove the entire engine with 9 bolts and rewired all wires with plugs, to unplug and move to the rear for severe work.

The transmission gear shift was swapped to the other side to put it on the right side. Replaced rear brake hose to work in with current front master cylinder.

I used the instrument panel from the 1100 and extended all wires up front. I used the cycle swith controls and placed one on the left side and other on the right. works great but took ten miles of wire.

Raised the gas tank 3 inches and the reverese unit is placed right under it. Had to make a new electrical panel to hold all of the electric stuff. I kept the wiring on the donor bike in tact, spliced in all rear wires to original tail lights. I moved the hydrolic clutch reservoir up front and ran new line down steel center tube to slave unit on front of engine. Moved radiator up front and built brackets for it and baffeling. Ran 20 feet of radiator hose up to the radiator. I am going to test drive unit and make sure all systems are working before I start closing it up. Lots of muffler work and enclosing engine.

I love the way that V4 runs. Dave was right when he said your in for a project.

by Don Muddiman......Sept. 2003

Your best bet is find a ZX7R engine. Look for a 1996 and later ZX7R engine. You want a complete engine with all the supporting parts. Radiator and all hoses, complete exhaust system with muffler, handlebar clutch cylinder assembly and hoses, air filter, all water hoses, thermostat housing, carbs, fuel pump, throttle linkage/cables, complete ignition system includes wiring harness, coils, ignition module, ignition switch (key not needed), alternator. Just get everything that the engine would need to run out of the bike. They typically call the above added items a car kit. The mini sprint races use this engine also. The going price for all of this will be somewhere between $1200 and $1600 dollars in 2003. You can also look for a motorcycle salvage dealer for all the above items. Make sure you talk to the owner before you lay your money out.

Why do we find most Pulses don't have more than 6,000 miles on them. The typical Pulse over heating problems with the YAMAHA engine may not be over heated at this time, but all the electrical components mounted on or near the engine have seen excessive heat more than once.

These engines don't function well when they are enclosed in fiberglass.

That's why the engine looks golden brown in color on the side cases. Most electrical components are good to about 150 degrees F, anything above that will destroy or weaken the component(s) creating a failure waiting to happen. My Pulse with the old 400 Yamaha engine and all others that have an air-cooled engine is doomed from this problem.

Here is what may have caused the engine to stop.

1) Electric fuel solenoid valve may be stopped up or has failed from excessive heat.

2) Ignition pickup coils mounted in the engine may have failed or are weak from excessive heat.

3) Alternator may have failed or possible shorted and or weak from excessive heat.

4) Ignition coils failed and or weak from excessive heat.

5) Fuel vapor lock in carbs from excessive heat.

Well this is just the beginning of things you are going to find running an air cooled engine in the Pulse especially in the Florida heat.

Oil leak problem may be a case gasket, loose drain plug or possible the engine has so has excessive blow-by the piston rings from over heating.

Knowing what I know now I would have never attempted to make an air-cooled engine survive in the Pulse. A lot of time and money was spent to try and over come the heating problem. I think Bob Cervero or anyone else that run the air-cooled engine and replaced that engine with a water cooled one will agree. Even adding the oil cooler up front helped, but was not a fix to the over heating problem.

If you really want to enjoy the Pulse just bite the bullet and install a water cooled engine. You have several choices to select from and lots of information available.

The Pulse is a neat and fun vehicle, but needs lots of modifications to make it reliable to enjoy.

Don Muddiman

I own Pulse #199 with a Yamaha 400cc (RJ) engine, I have found the owner before me had over heated the engine. Mechanically the engine is fine. I have already replaced the over heated burned up windings on the charging system stator, field rotor and wiring harness. After taking short hops (10 to 15 miles) I found the ignition started breaking down (dropping one cylinder) and shutting off completely for a fraction of a second after the engine would warm up. I also found the clutch started slipping. Yes I know I have check cable adjustment. :)

I decided to purchase a junked 1982 YAMAHA SECA 400 RJ for parts. After replacing and checking all the easy access ignition parts from the junked bike (coils, coil wires, plugs, ignition module, wiring) I still have the problem. The only thing left is to replace the ignition pickup coils (possible over heating damage also). On the 400cc RJ, they are located in the crankcase bathed in the engine oil. I had to choose fighting to remove the case cover while the engine was mounted in the Pulse or remove the engine. I decided to remove the engine and do a full inspection of it. From removing the canopy to having the engine on the bench took only an hour and thirty minutes. This was much easier than working on it in the Pulse.

After re-inspecting the charging circuit I have concluded the engine has been over heated thus causing the damage to the charging system. All the wires in the chain sprocket cover area have major heat damage. The oil sending wire and the natural wire insulation was also burned off. I work in failure analysis here at Lockheed Martin Missile Systems. I brought the stator assembly to work to view it under and optical a microscope.

My supervisor and I have concluded the wiring has seen excessive heat damage. The rotor and stator are both black in color and the varnish is flaking off the windings. I also found the electronic ignition wiring has heat insulation damage in this area. This Pulse had been parked for over two years in a barn, now I know why. The engine has 10,000 miles on it runs and sounds fine. I'm going to have a DSC done on the insulation to find at what temperature the insulation begins to melt. This way I will know about what temperature the engine has seen. I was planning on installing a engine temperature gage and finding this problem has re-enforced the installation of the gage. I got lucky on finding both parts at a local salvage yard for $100.

I found all this doing my first long test drive. Also during the test drive the engine started to falter and would not idle. Looking into this problem I had found both rubber carb mounts had torn allowing the engine to suck air. I now suspect this is all due to the engine being over heated and effecting the rubber properties. I have completely overhauled all the suspension parts and bearings on the Pulse chassis.

Analysis of the engine removed and tore down I found that the clutch was severely burnt up. The owner before me must have driven it for quite some time with the clutch slipping. I have never seen a motorcycle clutch or any other clutch burnt up this bad. The clutch assembly was dark and friction plates and disk were black. After seeing this and looking at the case discoloration on the lower part of the engine. You can clearly tell this was the heat damage that failed the other ignition and alternator components.

Slipping the clutch this bad would produced excessive high temperatures in the crankcase. Seeing how I work in failure analysis I had the wiring insulation analyzed for the melting point. The wiring insulation was found to start to melt at 525 degrees F. Hot enough to cause all this damage. It's amazing it did not catch on fire and do mechanical damage to the engine. I just finished installing the engine back into the Pulse. The engine runs and idles much better after replacing the bad pickup coils. One of the old pickup coils failed the ohm value test. A normal coil for this engine should have 116 ohms plus or minus 10%.

The one bad pickup coil had 50 ohms. This is why the ignition system was having such problems. I do have a 10-inch fan install to cool the engine area. I have found turning this on when the engine was hot at idle would drop the temperature 30 degrees in about a minute. The original fan was very inefficent and drew lots of amps.

Im still in the process of tweaking and changing things I have found wrong with the design. Oh yes on more thing I found while repairing the electrical system. The rectifier/regulator has a 10-gage wire coming from it to a terminal block (the terminal block is mounted beside the regulator/regulator).

From the terminal block to the fuse block in the front they used a 14-gage wire. This is much too small to carry the required current need. Then from there back to the battery for charging they use another 14-gage wire. This is over 22 feet of 14-gage wire that has to carry the current to charge the battery and power all the other electrical components. Its no wonder the charging system is marginal. You should never step down in gage size running a wire this far. It just cannot carry the current. I have add a 8-gage wire from the regulator/regulator to the fuse block.

I have also taped another 10-gage wire with a 30-amp fuse from the regulator/regulator to the plus side of the battery. This is the way it would have been on the motorcycle before it was removed and put into the Pulse. I can now run the Pulse at idle 1500 RPM with the fan and headlights on and battery is now charging. I have not drove the Pulse at this time for a full test run since all these repairs. I still need to do some minor things before I drive it again.

This is a pic of the Yamaha 400cc from the XS400RJ owners manual

YAMAHA 400cc CARB REPAIR by Don Sucha

Our Pulse #246 has a 1982 Yamaha XS400RJ dual overhead cam engine. The earlier Yamaha 400SJ is the single overhead cam engine.

There are no carb kits as such that I know of, but individual parts are available from Yamaha and expensive. The local Yamaha dealer quoted the following still available. Needle & seat $79.94, Float $35.23, Gasket kit $7.87, Throttle slide / vacuum diaphram assy $190.00, Rubber crab mounting isolator boot [carb to cylinder head] $55.64, [the carb boot is available only for 1 side but can be turned over upside down for the other side]. Carb isolator 0-ring, $6.01

All this times two since there are two carburetors. Prices seem to vary from dealer to dealer.

You don't really need a carb kit anyway, usually the carbs just need a real good cleaning with carb cleaner and compressed air. Be careful not to get the carb cleaner on any rubber parts, diaphrams or gaskets. Pay special attention to the cold enrichment jet [choke jet] and passages because the jet is very small and is hard to clean. It is often plugged from stale gas leading to hard starting when cold. Sometimes several attempts to clean this jet are required.

Bob Cervero

I put a Kawasaki ZX7, 750 into Pulse #61. It was great. Very fast and with a radiator up in the nose it never over heated. I had to beef up the sprocket attachment to the rear wheel.

Don Muddiman did the same install. One weak point was the adjusters in the swing arm. He tried doing a burn out and bent the adjuster bolts in the swingarm.

A Kawasaki 1100 would be a killer if it would fit.

Steve George

The Yamaha engine

needs cool air to function and run properly, the inside of the Litestar/Pulse being so aerodynamic,

poses problems getting air just for the engine to breathe, let alone cool. Also I would suggest when

the engine is apart to beef the clutch up with heavier springs and discs, clean the fins and engine

compartment of dirt and grease, might as well!!

Don Muddiman

Hey Steve,

Good point about beefing up the clutch up with heavier springs and discs. I tried to purchase heavier

springs when I reinstalled my clutch. I found the manufactures had discontinued supporting this 400cc(RJ)

engine because of its age. But what I did do is add shims under the springs to increase the spring load.

Spark plug ring gaskets make a perfect shim for doing this.

I added .030 shims under each spring. I would of added up to .125 if I had enough shims at the time. This would increase the spring load significantly. With having a foot clutch lever this would not of been a problem pushing in the clutch. Also check the spring length and make sure it meets the manufactures specs. I have images of all of this and a lot more of all the modifications I have done.

Don Muddiman

After

replacing the defective ignition pickup coils the Pulse ran fine on a few short hops again.

Well that all changed after a 60 mile run in stop and go traffic. I stopped for a red light and the Yamaha engine shut down. I jumped out and pushed it to the side of the road with my wife steering. She asked me what's wrong with it now? I thought, well maybe it needs CPR, seeing how its a Pulse.

I jumped back in and turned the key, damn it started. I then turn around and headed for home. After cursing for about 8 miles at 65mph the engine started to miss and drop rpm until it finally died again. This is got to be a heating problem. I removed the engine hatch cover to help let the cool. Yes I always carry tools and a cell phone on these test hops. Waiting for about 10 minutes I turn the key again and it started I put the hatch back on. We hopped in and ran for about another 5 miles until it did the same thing. Ok now I know for sure its a heat problem. I removed the hatch again and waited 5 minutes, it started. I left the hatch off this time and made it the remaining 12 miles home with no problem.

Lets think about this. Engine hatch on, Im running at 65mph and plenty of air should be coming in the air scoops at this speed, I had the fan running all the time and the ignition system still failed until I removed the hatch.

As I looked over the engine compartment I realize the ignition coils are mounted at the top aft of the compartment. The engine head temperature normally run between 350-375 degrees F for a air-cooled engine depending on ambient temperature. This means that the ignition coils are seeing excessive heat. I bet if I move the coils to a cooler place the problem disappear. After looking at my mounting options I decided to mount the coils on the backside of the deflectors coming from the NACA ducts.

National Advisory Committee for Aeronautics (NACA) the group that designed the NACA duct...... which is a bottled-shape, low drag air intake design.

National Aeronautics and Space Administration....(NASA)

NASA duct or scoop....A frequent, but incorrect term for a NACA duct or scoop.

About an hour and a half later I had completed rewiring and mounting the coils in their new home. Ok Lets take this baby for another test ride. After about 70 miles of continuous travel (stop and go/hi-way speeds) the engine never once faltered.

I recommend all Pulse drivers with air-cooled engines to move all electrical components (wires excluded) to the outer edge of the engine frame where it is much cooler. The heat just below the engine hatch must be pushing close to the engine head temperature of 350-375 deg. F. The original coils were mounted less than 10 inches from the heads.

No wonder the coils were failing. I plan on installing thermocouples to monitor the engine temperatures at various places in the compartment. Oh just for information normal exhaust temperatures reach1200 degrees F. Insulating the exhaust would be a plus to keep temperatures down. I'll let you know my findings.

Side Hatch Fan: 10 3/4" from AutoZone - MFG. Imperial Automotive Products P/N 226110

Dave Bauer #167

Part of the problem with the water-cooled machines is that they used the same radiator as was installed on

the donor bike. Unfortunately, they did not place the radiators in a location that could make good use of

the airflow. One solution is to add an airscoop as many have done. Another is to install a larger radiator.

I installed a radiator off of a 750cc bike to cool my 500cc. Worked great. I am in the process of installing

a GL1000 engine in my machine and am going to use GL1800 radiators.

The Honda GL1500 might not be good choice for the Pulse. I am not sure it will fit.

The drivetrain is too long. Welding and fiberglass work will be needed.

I looked into the 1500cc back when I converted my machine. I thought the distance from the front of the engine to the back of the rear wheel was too long. Perhaps you could come up with a way to modify the frames of each machine to make it fit, but it would be very close. Even so, you would have to cut out part of your body sides to accomodate the valve covers as the Pulse body is too narrow.

I ended up using a GL 1000 frame and engine. A GL1100 or 1984 GL1200 frame should also work. I don't think an '85 to '87 GL1200 would work because they are 4 inches longer.

Good Luck,

-Dave

Scott Enerson

If you decide to re-power your

Pulse with a Honda 1200cc, look for a 1986 or 1987.

Both the 1984 and the 1985s had carburetor problems.

I would use only the top of the line Aspencade which has a 7 digit odometer. So you can tell how many miles are really on the bike. I found one with 30,000 miles in 2022 for $800, and perfect running carbs. Facebook Market Place is just full of bikes. Anything newer will not have a steel, two sided swingarm to mount your reverser on to.

Steve George

I swapped the anemic 400 Yamaha for a 750 Suzuki. That process involved a lot of work including sectioning

the frame rail and making it removable for future engine removal/replacement. The mounts had to be fabricated

from original mounts from the donor frame and modified to fit in the Litestar, and an entire exhaust system

fabricated from scratch to fit inside the bodywork, and then a cooling system consisting of a themostatic fan,

plenum, and ductwork, scoops and actuators inside and outside of the body for proper airflow.

The engine came from a 1980's Suzuki bike that was wrecked, the frame work cut away from the engine saving the mounts.

The old Yamaha engine-compartment cleaned up, frame sectioned, engine lowered into the bay and alignment made for the mounts, exhaust and chain run all this while the engine was suspended on a hoist hanging in the engine bay, the mounts welded in place and the engine finally supported by the Litestar frame. The exhaust was then fabricated and fitted, as well as the wiring, clutch, chain, airbox, etc.... the entire process took a little over 4 months working nites and weekends.

Not easy. The cooling scoops added, and a fan installed where the rear seat used to be a box built around it and controls added, then the testing!

I can now remove and replace the engine assembly with the same engine in little over two hours using a few common tools, and a hoist. Thats planning!!

by Don Muddiman....Oct. 2002

How about using the Moto Guzzi 1000cc?

This air-cooled engine with automatic transmission will generate additional heat. Most of you have already seen the golden tan on the engine case of Yamaha 400cc from being overheated. I think the fiberglass would turn golden brown with small flames on a hot day using this setup. Yep, it would be a hot setup and attractive for a short time. The Pulse enclosed engine environment needs a water cooled engine. No matter how big and how many air-scoops you install for a motorcycle air-cooled engine you will never cool it sufficiently for reliable transportation. It will be prone to overheating.

Think of the engine like a wood stove, the more wood you put into it (larger cc) the more heat it will produce. The oil cooling system was hardly sufficient for the Yamaha 400cc at high ambient temperatures. Even though the oil temperature was at a tolerable level in the crankcase, damage was being done to the top end where most of the heat is generated.

Some people wanted my old engine and I told you it was not worth the cost of shipping. I had already rebuilt the top end twice from heat damage and it had finally died again just before I decided to install the Kawasaki engine. I was able to put 10,000 miles on the Yamaha engine in the Pulse before I finally realized this was not the answer.

Cooling an engine with an oil-cooler is only about 35% efficient and water is about 60% efficient. In an air-cooled engine the oil flows from the crankcase to the cylinder head to lubricate the cam shaft(s), valves and timing chain(s). The oil then returns via drain ports to the crankcase and then completes the loop again. These engines were never designed to dissipate heat via the oil system.

After many trials of adding scoops, fans and extending the package tray deck height it was the only option I had left. Yes it worked, but it was not the real answer to the problem and was only delaying the damage to come. In a water cooled engine the cylinder walls and head(s) have water cavities to transfer the engine heat via water to the radiator.

This is why I say, No matter how big and how many air-scoops you install in your Pulse, a motorcycle air-cooled engine will never cool it sufficiently for reliable transportation. A Volkswagen engine they are not.

Don't waste your time and money on installing an air-cooled motorcycled engine in a Pulse, it's not the answer to the problem.

The Pulse is a very unique vehicle. You want a vehicle that you can turn the key and drive. You don't want to worry about if you going to make it there and back. If this was your primary transportation you would want it right especially for the price some of us have paid. There is lots of enjoyment to be had. Believe me it's a blast when you can just crank it up and go where ever you want.

I have just purchased a 1997 Kawasaki 750cc Ninja sport bike engine to install in my Pulse. I have done a lot of research on this in 2002, looking at specs and taking measurements. I have concluded the Kawasaki engine is best suited for installation in the Pulse. Yes it's true the Goldwing does have a slightly higher torque at the lower RPM. I have found the 750cc sport bike engine develops about 75% of the torque at 3000 RPM compared to the Goldwing engine at the same RPM. The sport bike engine than surpass the Goldwing engine in torque and horsepower after it reaches about 6000 RPM.

I have been riding a Yamaha FZ750 sport bike (inline 4) I repaired that my nephew gave me. I am very impressed with the torque at low RPM, even when the bike has two people on it. I was concerned at first that the sport bike engine would be turning a much higher RPM at the same road speed than that of Goldwing engine. Running my 1982 Goldwing at 70 mph the engine is turning 4100 RPMs, the sport bike engine at the same speed is turning 4600 RPMs. Only a 500 RPM difference.

This sport bike engine has awesome power beginning at 3000 RPM and kicks into ABs at about 6000 RPM. These are highly precision engines and should last a long time running in a Pulse. I thought the Goldwing engine ran smooth until I rode the FZ750cc Yamaha sport bike, man these inline 4 cylinder engines are smooth. Another plus for using a sport bike engine is there no major cutting, welding, the charging system puts out 25amps+ and much less down time for installation.

The Kawasaki ZX750 (inline 4) is water and oil cooled for longer engine life and that's a plus when it comes to surviving in the Pulse. The ability to change my final gear ratio is also a plus and the engine is almost identical in size as the Yamaha 400cc. Riding the Yamaha FZ750cc I have been getting 45+ mpg even when I have been making it breathe hard.

Another plus is being able to use an automotive rear tire typically used on the Pulse . From what I have read about the guys running sidecars they recommend running a flat treaded tire which no one sells any more. One other option they talked about is to use a Volkswagen rim and tire modified to fit the Goldwing hub. A typical motorcycle tire in a LiteStar/Pulse setup will wear out in about 10,000 miles because you will be running only on the center of the tire.

There is also a safety concern that the vehicle spins out easier using the cycle tire because of minimum tread area contacting the road. Another concern as Dave Bauer has found out is the rear tire skidding during hard breaking. This is happening because of using a motorcycle rear tire that has little road surface contact.

The only negative part using a sport bike engine is the chain and sprocket setup. Using an o-ring chain will increase the life by about ten times over a regular chain. I have looked the Goldwing over many times and just can't justify spending a major amount of time installing it when I can use a sport bike engine.

After driving both the sport bike and the Goldwing and looking at the horse power and torque curves it just is not worth it in my opinion to install the Goldwing engine. The new sport bike engines generate lots of horsepower and torque, even at low RPM. I may be wrong but the only way to find out is to do it and then do a side by side drag race. Check the specs out on these new sport bike engines against the Honda Goldwing, I think you will be surprised as I was.

Robert Cervero........

I'm the previous owner of Pulse #61 and did the install of the 750 Kawasaki. Don Muddiman and I worked together to figure out how to make this motor work in a Pulse. He put the same motor in his #199. Both Pulses were greatly improved by this installation.

We chose to go with the Kawasaki after lengthy discussions for several reasons. We did not want to modify the Pulse frame or body. We wanted to retain the automotive wheel on the rear. Pulses don't lean in corners. We also did many measurements of the Kawasaki to ensure it would fit in the space occupied by the 400 Yamaha. And it would be cheaper than the Honda.

I bought a wrecked Kawasaki 750 for $800. It was complete and ran but needed a new radiator because of the wreck. Don bought a motor and all accessories to make it run on Ebay for $1,200.

You need to remove the Yamaha 400 and put the new motor in its place and fab new motor mounts. Then mount the radiator up in the nose of the Pulse and run water lines to it. The stock exhaust fit perfectly with the Pulse body and frame and only required one cut and re-weld. You need to figure out how to activate the clutch. The Kawasaki clutch was hydraulic so I used the Pulse clutch cable system to pull on the Kawasaki clutch master cylinder and it worked fine.

As far as the Kawaski 636, I don't know much about that one. As long as it will fit in the frame, why not? I assume it's a chain drive motor? That also will let you experiment with different sprockets to optimise your set up.

Bob Hichborn..............

I haven't integrated a Honda Goldwing GL1500 into a Pulse yet, but I don't think it would present any issues that would be "show stoppers". The wheelbase of the Honda GL1500 is spec'd at 66.5 inches which is roughly 3 inches longer than the GL1100 at 63.4. The GL1500 also has a 6 cylinder powerplant vs the GL1100's 4 cylinder. So, more horsepower and smoother ride. The jewel for us Pulse owners is the GL1500's REVERSE GEAR.

Looking at my Pulse #77, it looks like hiding the extra 3 inches within the frame and body panels shouldn't present any particular problems. There is a 200 lb weight differential between the GL1100 and the GL1500, but I'm not sure how much of this is associated with parts that are removed when the donor bike is stripped.

My feeling is that, in general, you can integrate anything you want into the rear of the Pulse. It's just a matter of how much welding or body work you care to do.

"Everyday you wake up with a Pulse, is a good day!"...............Bob Hichborn

Steve Cole

I have the factory installed oil temp gauge with the Yamaha XS400 RJ. The sensor is made by VDO, the brand of

all of the gauges. It is installed in place of the oil drain plug and should be an easy add on for anyone.

The gauge indicates from 180 to 250 degrees on a 58 degree day.

Michael Boyson

I put a small fan on my ignition system because it would begin to stall when it got hot. This seems to do

the trick.

I also ran a flexible hose from the aircleaner intake to one of the side scoops so the engine gets cool air,

not the hot air under all that fiberglass.

From Robert McRay....

Try this...... the "exhaust thermal wraps" to bring down the engine compartment temperatures. Before I applied them, my engine compartment (ambient temperature) was getting pretty hot. Now, even after a long drive, the compartment is barely lukewarm... They are incredible!... One word of warning though... When they are first applied they smoke a lot. It's part of the curing process but really adds to the effect when you're driving down the street. Then there's the smell (these two things only last a short while). Once they are fully cured you never have to worry about things getting too hot in that small space again.

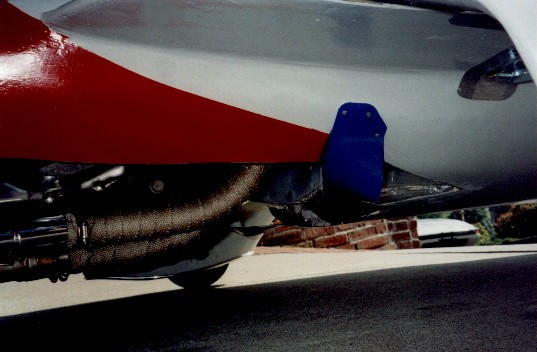

The above pic shows the muffler "thermal wraps" (okay the lower portion of them) and the "air scoops" that I cut out of the bottom. As you can see, I attached a plastic strip which is bent in the middle to throw more air up into the engine compartment. Works great!

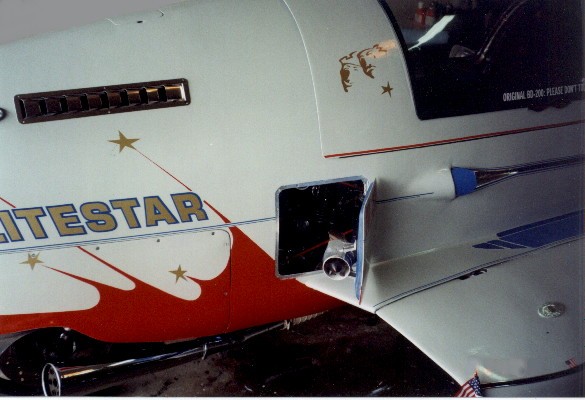

Above pic shows the engine compartment door on the BD-200. The engine door wide open to see the turbo fan. These doors are controlled by the left hand lever and I can switch them on and off by the switch panal on the right side of the dash.

Tom Caprioli

I bought two turbo fans to help with my overheating

problem (liquid cooled BMW K100 with internal radiator, talk about heat buildup)

Turbofans:

http://mirror.shipstore.com/SS/HTML/ATT/ATT17414.html

Wrap exhaust pipes to help eliminate heat buildup.

Thermowraps for the exhaust pipes:

http://lockhartphillipsusa.com/hightemp.html

Last Update: 11-20-20......

Disclaimer:

Litestar Pulse Website is provided to you free of charge, "as is."

The best efforts to maintain accurate Litestar Pulse

Website history, information, repair tips and content, however, it is

not responsible for the content of its information, opinion providers.

You should not assume that Litestar Pulse Website is error-free and

makes no guaranties as to the accuracy, currency, content, or quality

of any such information.